The Beginner's Guide To Roof Flashing

Table of ContentsWhat Is The Purpose And Types Of Commercial Roof FlashingHow Roof Flashing Works - Ask The ExpertWhat Is Roof Flashing And Why Is It Important? (Protecting

Remember, your flashing ought to outlast the roofing system it was initially installed on and will not constantly require to be changed throughout a roofing system replacement. If flashing is one roof product that may need to be changed during a roofing replacement, what other roofing products need to be changed? Fortunately for you, we have actually got you covered. Our craftsmanship ensures you get a new roof that lasts for decades. So, what roofing materials are changed when you get a new roofing? Read our post on the 9 Materials Consisted Of in Your Roofing Replacement to discover whatever that comes with a full replacement. by Kenton Shepard and Nick Gromicko, CMIThe purpose of the.

series.

https://www.google.com/maps/embed/v1/directions?key=AIzaSyAT8ig6vIZpArpz5aokN-7eevoH-Unfy0Y&origin=32.1433135,-110.9163409&destination= Tucson&mode=driving

" Mastering Roofing Inspections" is to teach home inspectors, along with insurance and roof specialists, how to recognize correct and inappropriate conditions while checking steep-slope, domestic roofings. This series covers roof framing, roofing products, the attic, and the conditions that affect the roof materials and.

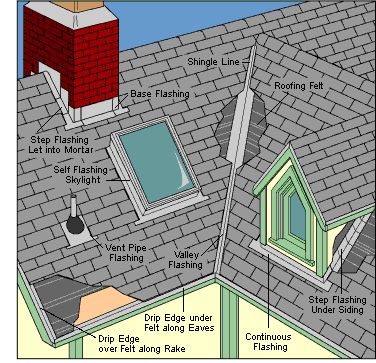

parts, including wind and hail. They're called headwalls and sidewalls. A headwall is a level junction where a roofing satisfies a wall. This illustration reveals correct flashing at a headwall condition. Headwall flashing need to extend up behind the exterior.

Roof Flashing Details

wall covering and down over the roof-covering product, as you see here. This is real no matter what type of roof-covering material is installed. Do not error this condition for headwall flashing routed beneath the shingles and call it a flaw. No minimum headwall flashing measurements are provided that are appropriate to every manufacturer and jurisdiction, so you're only concerned with seeing that headwall flashing is set up in a way that will keep the water out. Headwall flashing normally comes bent to 120 and can be relatively easily flattened for roofs with shallower pitches. Periodically, you'll see a roofing which has actually had 90-sidewall flashing installed as headwall flashing. These don't bend well to accommodate roofs with steeper pitches, and you'll frequently see spaces beneath the flashing. A sidewall is a junction between a wall.

Roof Flashings

and a sloped part of a roofing. Other than where walls are brick, the vertical part of the sidewall flashing need to extend up behind the outside wall covering, simply like with headwalls. The horizontal part of the flashing will differ, depending upon the kind of roof-covering materialSidewalls on roofings covered with asphalt shingles, wood shingles, shakes and slate.

needs to be flashed using action flashing, like you see here. All shingle manufacturers need step flashing at sidewalls for both asphalt, wood and slate. If you see constant, one-piece flashing like this utilized as https://www.dcroofingarizona.com/commercial/roof-coatings/ sidewall flashing with shakes, shingles or slate, it's a faulty installation, no matter how often you see it.

How Roof Flashing Works

Here's an example of an asphalt shingle roofing system with constant flashing set up. Rather of setting up the step flashing between shingles, the flashing rests on top of the shingles. It's not unusual to see sealant set up when sidewall flashing is missing out on. Sealant will ultimately dry, diminish and break. You'll see sealant replacemented for flashing in a great deal of various areas on roofing systems. When you see it, you must recommend replacement with correct flashing, or yearly examination and re-application of a proper sealant, as necessary. You can probably raise the butt of the lowest tile enough to see. Pan flashing is continuous flashing that has a lip on the flange which extends beneath the tile so that the horizontal part of the flashing acts as a water channel. Step flashing size requirements vary according to maker. You'll typically see outside wall coverings set up right down on top of the shingles. Without a gap, the outside wall covering can wick up wetness from the roof. This can result in decay, delamination, peeling paint, and other issues. This condition is specifically common on roofing systems with several layers of shingles.

All About Roof Flashing

You can see it in this photo if you look at the base of the sidewall just to the left of the downspout termination. Looking at this very same location, you'll see that several tiles are interrupted. Unless the pan flashing is relatively broad, this may enable adequate wetness entry to trigger a leak, and it needs to be pointed out in your inspection report.

You 'd desire to check this area carefully to assess the possibilities for moisture surpassing the tile. At the within corner, the headwall flashing that extends out over the tile was not set up high enough. If you don't see a gap, you will not be recommending correction, however you need to point out in your examination report that the exterior wall covering has inadequate clearance from roof-covering products.

Mono-slope Roof Flashing

Roofing flashing supplies extra defense for roofing locations that are vulnerable to water seepage. The purpose of flashing is to direct the circulation of water that leaks into intersections down and far from the interior of the structure to the topside of the roofing material. The majority of flashing is made from galvanized metal or aluminum and should be installed around the chimneys, skylights, soil and vent stacks, HEATING AND COOLING systems, roofing system valleys and likewise where roofing decks and walls converge and where water is susceptible to gather.

https://www.youtube.com/embed/LXxNbsNc144

DC Roofing of Arizona

Tucson, AZ

(520) 979-9095

https://www.dcroofingarizona.com/

Each of these systems should be set up properly for the system to work as created. Right setup is even more important when it comes to flashing. In every kind of roof, the leading edge of the flashing passes underneath the underlayment, the upper pieces of flashing pass over the lower pieces, and the lower edge of the flashing always passes over the top of the roof product.